Case Study- Carbon Fiber Parts

Why CFRP for BIW Replacements?

» Light weight and ability to form skin thicknesses from 0.8 mm

(typical 1.25 mm thk.)

» Customization of strength, stiffness and weight.

» Can be combined with other materials like Kevlar to offer greater

impact protection.

» Can be painted and lacquered easily to Class A surface finish.

CFRP- Bonnet assembly

» Light weight (almost 40% lighter than existing metal bonnets).

» Significantly shorter development time 2 weeks against 6-8 weeks

» Prototype project cost of less than 25% against existing bonnet development cost.

Car Bonnet

Car Bonnet

Sports Car-Gall away door

Sports Car-Gall away door

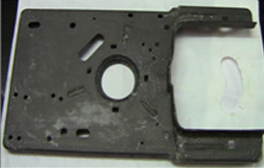

Motor Mounting Bracket

Motor Mounting Bracket